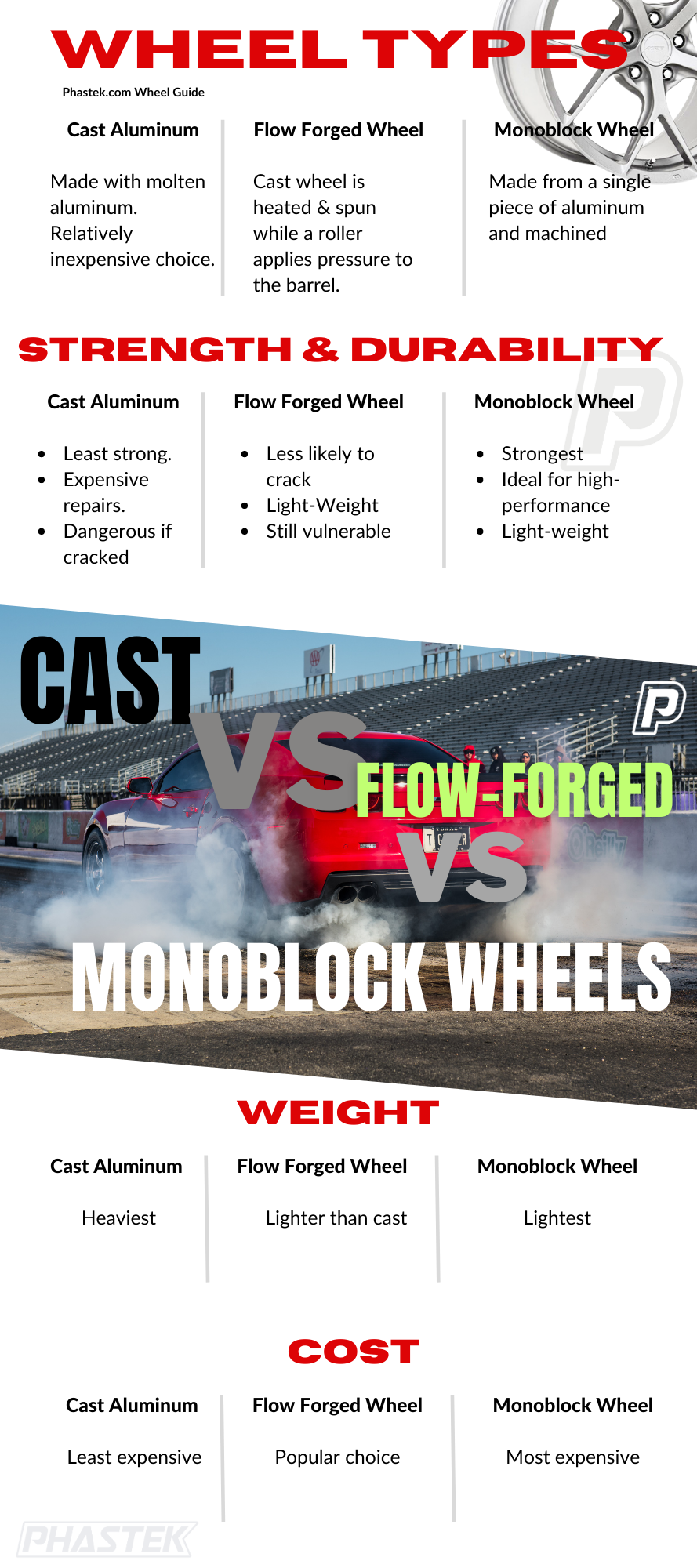

What is the difference between cast, flow forged and monoblock aluminum wheels?

Choosing the right wheel for your vehicle is a tough choice. It’s also an expensive choice so it's important to understand the different types of wheels and how they are used.

You want to purchase a durable, long-lasting wheel. But if you’re running down the track, you’re likely also looking for something light-weight that will last.

We’ll look at cast aluminum wheels, flow forge aluminum wheels and monoblock aluminum wheels.

How are these types of wheels made?

● Cast aluminum wheels: Cast wheels are made by pouring molten aluminum into a mold that is left to cool and harden. This is a simple and inexpensive process - making these wheels a popular choice.

● Flow forged aluminum wheels: Flow-forged wheels are made when heating a cast wheel, then spun at high speeds while a roller applies pressure to the wheel barrel. This process compacts the aluminum, and increases density.

● Monoblock aluminum wheels: Monoblock wheels are made by forging a single block of aluminum under high pressure and heat. This results in a wheel that is strong and lightweight.

What are the stronger & more durable wheels?

● Cast: These are going to be the least strong. Cast wheels are prone to bending and cracking under stress and impact. This results in dangerous situations and expensive repairs.

● Flow forged: These wheels are stronger and more durable than cast wheels. They are less likely to bend or crack under impact, but are still more vulnerable than monoblock wheels.

● Monoblock Wheels: These are the strongest and most durable of the three. Their ability to withstand stress and impact without bending or cracking makes them ideal for high-performance vehicles.

Recent Posts

-

-

Tariff Alert: Beat the Price Hike on Wheels & Body Components

.blog { line-height: 1.5; } .bloglist { list-style: disc!important; } .blog + .blog { border-top: …Apr 10th 2025 -

Camaro Models by Year: An In-Depth Look at Chevrolet's Iconic Muscle Car

Welcome to our journey through the storied past of the Chevrolet Camaro, a quintessentia …Dec 15th 2023